2020 Good Quality Metal Casting Molds - Stainless pipe clamp of casting parts – Ideasys

2020 Good Quality Metal Casting Molds - Stainless pipe clamp of casting parts – Ideasys Detail:

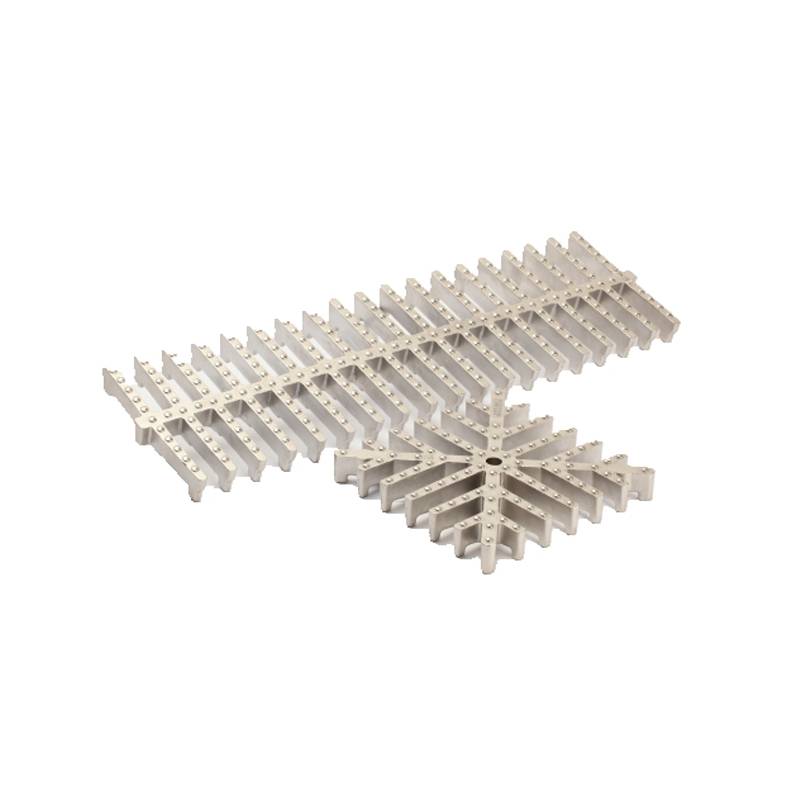

| Produst | Name | Material | Application | Casting tolerance | Weight |

|

Stainless pipe clamp of casting parts | HK | Thermal power plant | ISO 8062 CT7 | 1.07 kg |

It is not desirable to add a thick clamp directly to the pipe on the fast flux test device, because the metal temperature difference between the pipe wall and the clamp may significantly reduce the thermal fatigue life cycle capability of the pipe. Special attention should be paid to prevent adverse cracking of insulating materials, maintain the required clamp stiffness during seismic events, minimize the constraint of clamp on the pipeline during normal pipeline heating, and prevent the clamp from rotating on the pipeline.

Drawing→ Mold → Wax injection→ wax tree assembling→ Shell moulding→ Dewax-buring→ pouring→ Shell removing→ Cuttiing-Griding→ Machining → Deburring → Surface Finishing → Assembly → Quality Inspection→ Packing

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for 2020 Good Quality Metal Casting Molds - Stainless pipe clamp of casting parts – Ideasys , The product will supply to all over the world, such as: Somalia, Lesotho, Argentina, Business philosophy: Take the customer as the Center, take the quality as the life, integrity, responsibility, focus, innovation.We will provide professional, quality in return for the trust of customers, with most major global suppliers,all of our employees will work together and move forward together.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!

Write your message here and send it to us