Fixed Competitive Price Horizontal Milling Machine - Connector on boiler heating system – Ideasys

Fixed Competitive Price Horizontal Milling Machine - Connector on boiler heating system – Ideasys Detail:

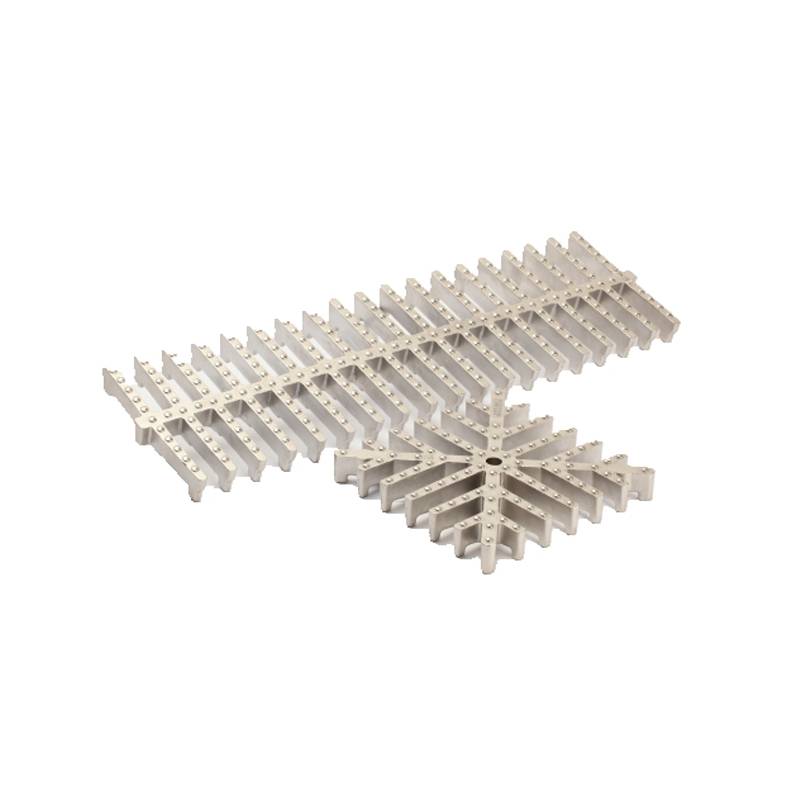

| Produst | Name | Material | Weight |

|

Connector on boiler heating system | Brass | 105g |

How are brass fittings made?

The first step in this process is to cut the copper bar into the length of the part being made. It is then heated to achieve permeability and pressed between the dies under high pressure. It is then cooled, and the flash is trimmed and the forging blank is machined to complete the assembly.

Why do we use brass?

Brass is most widely used in decoration and mechanical fields. Due to its unique properties, including corrosion resistance, common uses of brass include applications requiring low friction.

Why use brass for gas fittings?

Brass can also withstand low temperatures. This is important because vaporization of LPG causes cylinders and valves to become very cold. Brass is not brittle at low temperatures, unlike mild steel.

Does brass corrode in water?

In general, the zinc loss of brass after immersion is relatively fast, which leads to metal weakening and makes its structural integrity in danger. In addition to immersion in water, brass is a very suitable metal for outdoor applications due to its amazing durability.

Drawing→ Mold → Wax injection→ wax tree assembling→ Shell moulding→ Dewax-buring→ pouring→ Shel removing→ Cuttiing-Griding→ Machining → Deburring → Surface Finishing → Assembly → Quality Inspection→ Packing

Product detail pictures:

Related Product Guide:

Responsible excellent and fantastic credit rating standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, buyer supreme" for Fixed Competitive Price Horizontal Milling Machine - Connector on boiler heating system – Ideasys , The product will supply to all over the world, such as: Comoros, Rio de Janeiro, Georgia, The quality of our products is equal to OEM's quality, because our core parts are the same with OEM supplier. The above products have passed professional certification, and we not only can produce OEM-standard products but we also accept Customized Products order.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.