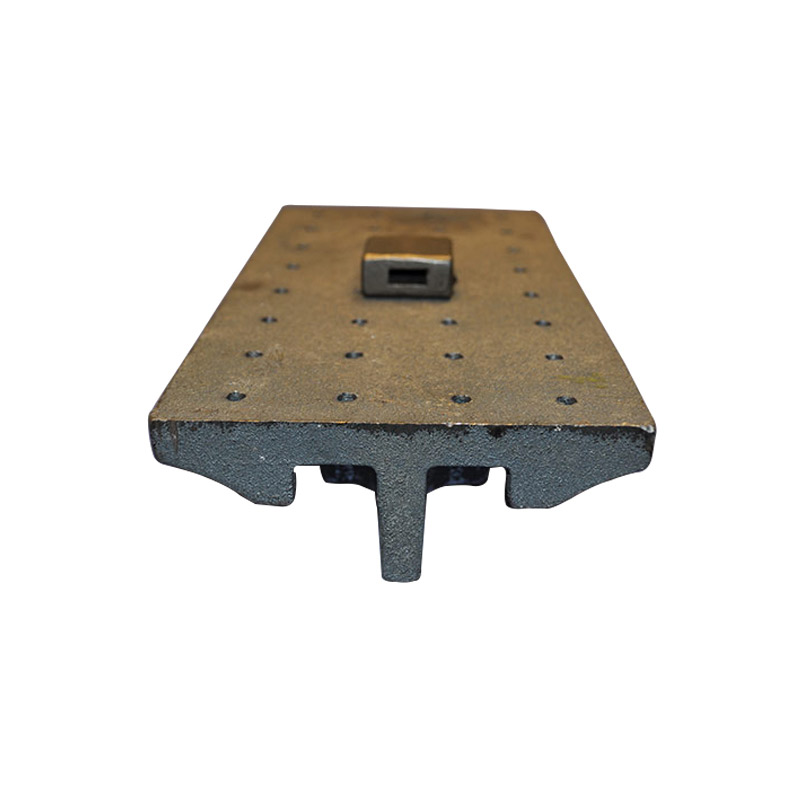

Stainless steel grate for thermal power plant

| Product | Name | Material | Application | Casting tolerance | Weight |

|

Stainless steel grate for thermal power plant | 16Cr20Ni14Si2 | Thermal power plant | ISO 8062 CT7 | 6 kg |

|

Casting Grate made in China | HH | Thermal power plant | ISO 8062 CT7 | 4.4 kg |

|

Custom grate used for thermal power plant | HH | Thermal power plant | ISO 8062 CT7 | 3.8 kg |

Power plants use boilers to produce high-pressure steam to generate electricity. This process is called the Rankine cycle. Boilers obtain energy from some form of fuel, such as coal, natural gas or nuclear fuel, and heat water to steam. In addition to a small part of the primary energy in the world comes from fuel, the remaining three-quarters of the fuel eventually goes into the boiler (the remaining fuel goes into the internal combustion engine, which uses different fuels).

The grate is usually made of casting. After assembling, the necessary ventilation gap is kept between the plates, and a separate ventilation chamber which can adjust the air volume is often set at the bottom of the grate, so that the air can enter the fuel layer for combustion through the gap.

Drawing→ Mold → Wax injection→ wax tree assembling→ Shell moulding→ Dewax-buring→ pouring→ Shell removing→ Cuttiing-Griding→ Machining → Deburring → Surface Finishing → Assembly → Quality Inspection→ Packing