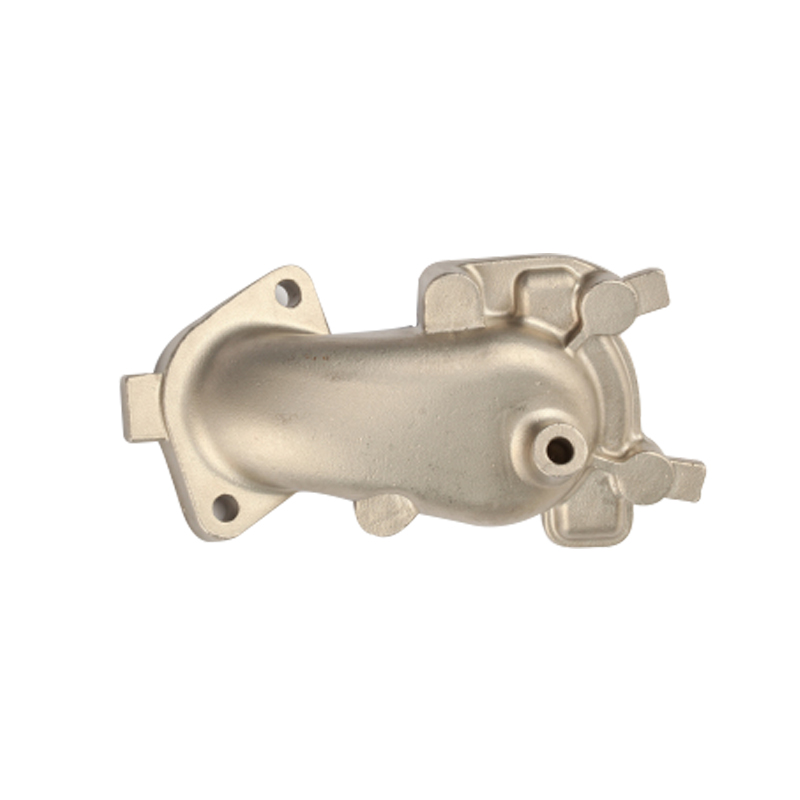

Manifold with CNC machined automotive parts

| Product | Name | Material | Application | Casting tolerance | Weight |

|

Manifold with CNC machined automotive parts | 1.4308 | Automotive | ISO 8062 CT5 | 0.36 kg |

The main function of the intake manifold is to evenly distribute the combustion mixture (or air from the direct injection engine) to each intake port of the cylinder head. Uniform distribution is very important to optimize engine efficiency and performance. It can also be used as a support for carburetor, throttle body, fuel injector and other engine components.

In a reciprocating spark ignition piston engine, there is a partial vacuum in the intake manifold due to the downward movement of the piston and the restriction of the throttle. This kind of manifold vacuum can be very large, and can be used as the source of auxiliary power of the vehicle, driving auxiliary systems: power auxiliary brake, emission control device, cruise control, ignition advance, windshield wiper, power window, ventilation system valve, etc.

This vacuum can also be used to extract any piston blowby from the engine crankcase. This is known as a positive crankcase ventilation system in which the gas burns with the fuel / air mixture.

Intake manifold has always been made of aluminum or cast iron, but the use of composite plastic materials is more and more popular.

Drawing→ Mold → Wax injection→ wax tree assembling→ Shell moulding→ Dewax-buring→ pouring→ Shell removing→ Cuttiing-Griding→ Machining → Deburring → Surface Finishing → Assembly → Quality Inspection→ Packing