This paper mainly introduces a kind of processing solution for turning the internal snap ring groove in the hole on the non rotating body, focusing on the main structure, use method, main principle, main advantages and so on of the tooling. For some special parts of the spring groove in the lathe processing has a certain reference, in order to fully tap the processing capacity of CNC lathe, improve the processing efficiency of trial parts is of great significance.

1. Raising of the problem

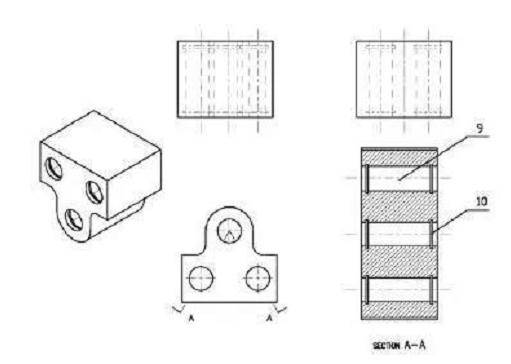

In the actual production and processing, we will encounter non-standard single piece or small batch of support parts as shown in Figure 1. The characteristics of such parts are as follows: there are unevenly distributed through holes on the side perpendicular to the installation bottom surface; there are snap ring grooves at both ends of the through holes close to the holes.

9: Hole 10: Snap ring groove

Picture 1

We usually use fitter marking – Drilling – reaming or directly use CNC milling machine drilling – reaming (boring) to process the bottom hole of the part. However, how to quickly and economically process a snap ring groove at both ends of the hole has become a more difficult and difficult technical problem to solve. The general method of processing the spring groove of this kind of parts by using modern numerical control processing technology is shown in Table 1. To sum up, the clamping times of the above 1-2 processing schemes are less, but the cost of equipment and cutting tools is high; 3-4 There are many times of clamping, but the cutting efficiency is high, and the quality of groove bottom is good. Therefore, combined with the cost of machine tool, cutting tool, cutting efficiency and other aspects, it is more economical and reasonable to use the ordinary CNC lathe to process this kind of parts, but the use of four jaw chuck for clamping and positioning is more cumbersome and easy to be inaccurate. Can the self centering three jaw chuck be used to solve the problem of positioning and clamping, so as to further improve the efficiency and reduce the cost of positioning and clamping?

2. The solution to the problem

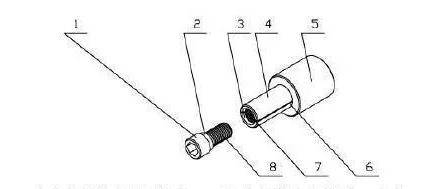

- The main parts are as follows: Hexagon bolt head end cylindrical surface; 2. Pinch hexagon bolt head end conical surface; 3. Main tooling expanding conical surface; 4. Theme tooling closing external cylindrical surface; 5. Theme tooling clamping surface; 6. Main tooling slotting; 7. Main tooling internal thread; 8. Hexagon bolt thread

Picture 2

2.1 main structure of tooling

The simple expanding tool for NC turning is characterized in that it is composed of a processed inner hexagon bolt and a main body expanding body; the processed inner hexagon bolt is characterized in that a matching conical surface 2 is arranged at the head end cylinder 1 side close to the thread end; the main body expanding body is characterized in that one end is provided with a three jaw chuck clamping surface 5, the other end is provided with a cylindrical surface 4 matched with the clearance of the hole of the part; the end of the cylindrical surface 4 is provided with an internal thread 7 connected and fastened with the inner hexagon bolt, the end of the internal thread is provided with a conical surface 2 matched with the conical surface 2, and the slotting 6 evenly divides the cylinder matched with the hole into three equal parts.

2.2 use method of tooling

① The clamping surface 5 of the clamping body tooling of the three jaw chuck;

② The main part is assembled with the outer cylindrical surface 4 and penetrated into the air where the part is processed;

③ Tighten the inner hexagon bolt to make the cone 2 and cone 3 fit together, and tighten the bolt to complete the clamping.

2.3 main principle of tooling

When the inner hexagon bolt is screwed in, with the fit of the cone 2 and the cone 3 (the diameter of the cone 3 is slightly smaller than that of the cone 2), the cone 2 forces the opening deformation of the cone 3, so that the end of the outer cylindrical surface 4 of the main assembly is expanded, so as to restrict the radial rotation and axial movement of the part hole.

2.4 main advantages of tooling

① Tooling design structure is simple, easy to use, low manufacturing cost;

② There is no need to adjust the center of the chuck to the center of the chuck;

③ The axial movement of the parts along the hole direction is controlled by the end face fitting, which can effectively control the position of the processing snap ring groove.

3. Concluding remarks

In the process of processing the product, we considered the initial four processing schemes, and made a detailed cost accounting and technical comparison. Only this kind of fixture with ordinary CNC lathe is the most economical, the most reasonable, the highest efficiency, the product quality is the most stable.

Post time: Jan-06-2021