OEM Supply Wax Casting Process - Lost wax casting Burner accessories used in petrochemical industry – Ideasys

OEM Supply Wax Casting Process - Lost wax casting Burner accessories used in petrochemical industry – Ideasys Detail:

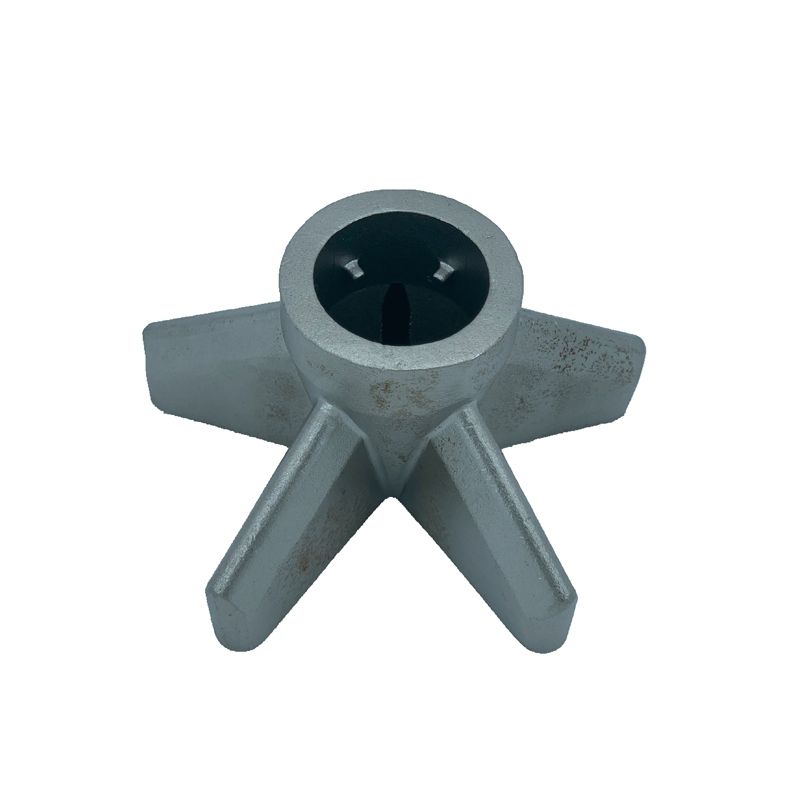

| Product | Name | Material | Application | Casting tolerance | Weight |

|

Lost wax casting Burner accessories used in petrochemical industry | HK | Petrochemical industry | ISO 8062 CT7 | 0.7 kg |

|

Green wax burner accessories | HH | Petrochemical industry | ISO 8062 CT6 | 0.29 kg |

The burner is designed according to API 535 standard and can be customized according to customer’s requirements.

Petrochemical plants convert natural resources such as crude oil, natural gas, ores and minerals into products, which are widely used. They produce many important components for industrial processes, including ethylene, propylene, butadiene and aromatics.

Burner is a kind of mechatronics equipment with high degree of automation. This kind of burner accessory is used in thermal power plant industry.

Industrial gas burners belong to industrial burners. According to the combustion medium, there are industrial gas burners and industrial oil burners.

The working principle of a gas burner is very simple. Fuel gas or air, or premixed fuel gas and air enter the combustion chamber of the burner. Stable combustion is taking place. The burner provides heating value for the application.

In the industrial sector, the most common fuel gases are acetylene, LNG and propane.

For applications, most industrial gas burners are used in industrial boilers and furnaces.

As a leading supplier of industrial burners, Ruichang adopts the most advanced combustion technology to produce reliable burners. It ensures that the burner has higher combustion efficiency while keeping emissions to a minimum.

Drawing→ Mold → Wax injection→ wax tree assembling→ Shell moulding→ Dewax-buring→ pouring→ Shell removing→ Cuttiing-Griding→ Machining → Deburring → Surface Finishing → Assembly → Quality Inspection→ Packing

Product detail pictures:

Related Product Guide:

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our service, we provide the products with the good quality at the reasonable price for OEM Supply Wax Casting Process - Lost wax casting Burner accessories used in petrochemical industry – Ideasys , The product will supply to all over the world, such as: Jakarta, Norwegian, Norway, Our Company has professional engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the products, Please feel free to contact us.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.