Short Lead Time for Micro Precision Machining - Mirror polished stainless steel glass clamp – Ideasys

Short Lead Time for Micro Precision Machining - Mirror polished stainless steel glass clamp – Ideasys Detail:

| Product | Name | Material | Application | Finish | Casting tolerance | Weight |

|

Mirror polished stainless steel glass clamp | AISI 304 | Hardware | Mirror polished | ISO 8062 CT5 | 100 g |

|

China factory Mirror polished stainless steel glass clamp | AISI 304 | Hardware | Stain Polished | ISO 8062 CT5 | 100 g |

Why use glass clamps?

We believe that glass clamps are the best choice for fixing glass railings or glass doors, because they are less risky than other options. Of course we will take care not to drill holes directly in the glass. For tempered glass, any attempt to drill through may cause the pane glass to break. So we will choose glass clamps.

On the other hand, the glass clamp will not cause any damage to the glass itself and can be adjusted during installation. If installed correctly, they will firmly fix the weight of the glass plate in place and prevent the glass plate from sliding or swinging.

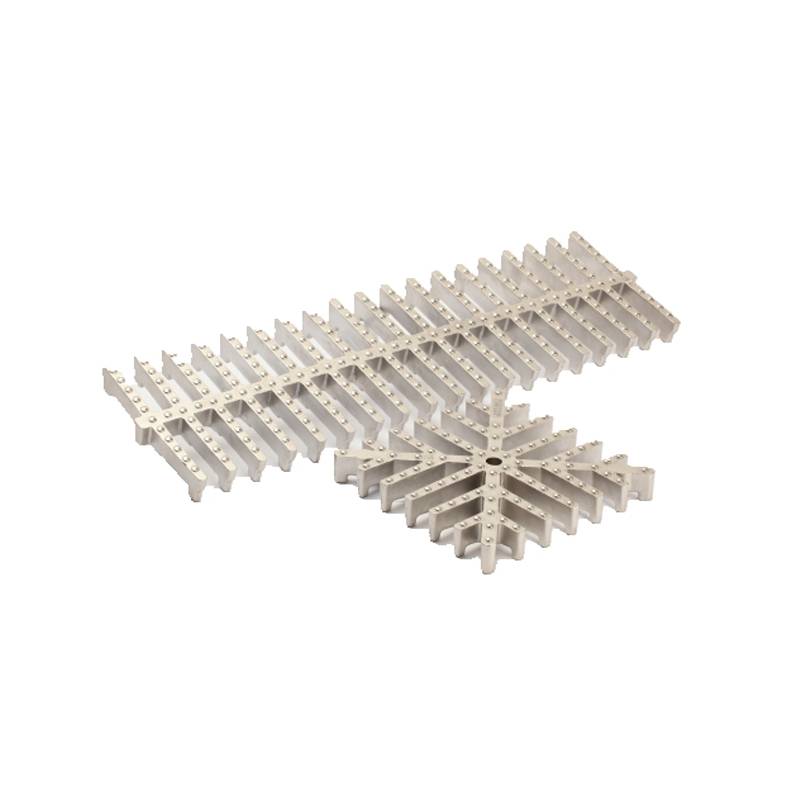

What does the glass clamp look like?

There are subtle differences between different models, but generally speaking, glass clamps consist of two parts. There is an L-shaped bracket, which is screwed into the supporting surface and then clamped. This is extra protective rubber and can be purchased in a round or sharp edge style.

Drawing→ Mold → Wax injection→ wax tree assembling→ Shell moulding→ Dewax-buring→ pouring→ Shell removing→ Cuttiing-Griding→ Machining → Deburring → Surface Finishing → Assembly → Quality Inspection→ Packing

Product detail pictures:

Related Product Guide:

We continuously execute our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management advertising and marketing gain, Credit history attracting buyers for Short Lead Time for Micro Precision Machining - Mirror polished stainless steel glass clamp – Ideasys , The product will supply to all over the world, such as: Denver, Kuala Lumpur, Jersey, All the imported machines effectively control and guarantee the machining precision for the products. Besides, we have a group of high-quality management personnels and professionals, who make the high-quality products and have the ability to develop new products to expand our market home and abroad. We sincerely expect customers come for a blooming business for both of us.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.